IN2 Innovation Project Spotlight

Redefining Beverage Innovation

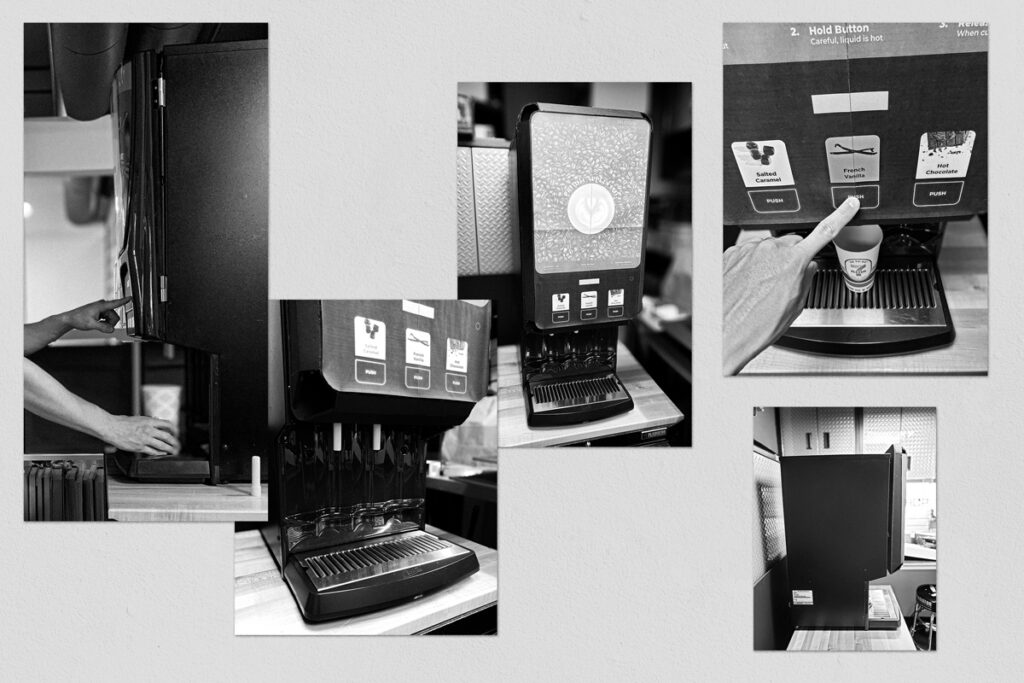

Wilbur Curtis, a leading manufacturer of beverage dispensing equipment, partnered with IN2 to revolutionize their Primo Cappuccino line, a family of commercial cappuccino machines commonly found in convenience stores. The goal was clear: modernize the product’s design and functionality to align with evolving customer demands while maintaining the high-quality standards customers associate with the Curtis brand.

IN2 tackled the challenge in two phases:

- Design Refresh: Focused on updating the visual and functional design elements of the machine’s front interface, drip tray, and user controls.

- Prototyping and Engineering: Advanced the design into pre-production prototypes with refined engineering data and optimized manufacturing solutions.

Challenges

- Modular Adaptability: The family of machines needed to accommodate configurations from three to six spouts.

- Cleanability: High-touch surfaces demanded a sleek, hygienic design that minimized crevices and was easy to wipe clean.

- User Accessibility: Simplified flavor labeling and maintenance processes for operational efficiency.

- Brand Integration: Ensured the design aligned with the Curtis brand identity while exploring visual cues from their GemX product line.

Design and Innovation Solutions

- User-Driven Aesthetic Redesign: IN2 conducted extensive research into market trends, incorporating sleek, modern elements inspired by home appliances that included more capacitive touch interfaces.

- Enhanced Cleanability: The new design minimized gaps and introduced wipeable surfaces, reducing maintenance burdens.

- Flexible Flavor Labeling System: IN2 eliminated the need for permanent decals by creating easily interchangeable flavor labels, maximizing flexibility for operators and branding opportunities for business owners.

- Garage Door Mechanism: By introducing an adjustable-door design, IN2 allowed the front panel to open from either the side or the top for easy maintenance access.

- Prototyping Excellence: IN2 created detailed prototypes that blended machined plastic components and Curtis-manufactured sheet metal, resulting in a seamless fit-and-finish for testing and validation.

Key Innovations

- Digital Interface Evolution: IN2 leveraged the best of both worlds and created tactile buttons with a more modern, visually appealing interface.

- Back Painting Technology: IN2 used this cost-effective method to achieve crisp, durable finishes on key plastic components, elevating the overall aesthetic and functionality.

- Optimized Lighting Design: Addressed transparency and diffusion issues to create an even and visually striking, backlit display.

- Material Innovation: Carefully balanced cost-effective components with premium finishes to ensure manufacturability without compromising quality.

Prototyping Excellence by IN2 International

The partnership with IN2 International was pivotal in creating a highly functional and precise prototype for the Primo Cappuccino Gen 4 refresh project. Key contributions included:

- Engineering Refinement: IN2 International translated refined engineering details into a working prototype, ensuring functional accuracy and manufacturability validation.

- Advanced Back Painting Techniques: This approach enabled crisp, high-contrast black edges on both lower and upper plastic components, improving aesthetic precision and branding flexibility despite minor label misalignments.

- Dual-Fabrication Approach: By coordinating seamlessly with Curtis’s in-house sheet metal fabrication, IN2 International handled the production of plastic components, balancing complexity with accuracy.

- Effective Coordination: IN2 managed communication and alignment between multiple fabricators, ensuring clarity on roles and deliverables to achieve a cohesive and fully functional prototype.

Impact and Results

The collaboration between Wilbur Curtis and IN2 resulted in a product that maintained the integrity of the Curtis brand while significantly advancing its design and usability. Key benefits included:

- Streamlined Operations: IN2 enhanced maintenance processes with modular design elements and improved accessibility.

- Elevated User Experience: IN2 created a sleek, intuitive design that stands out in busy retail environments while simplifying interaction for users.

- Manufacturing Efficiency: IN2 leveraged their own manufacturing expertise with IN2 International’s precision component prototyping and Curtis’s in-house sheet metal fabrication to accelerate time-to-market.

Client Success and Industry Integration

The project culminated in a final production-ready unit that remained true to the original concept, demonstrating IN2’s ability to seamlessly integrate design innovation with practical manufacturing constraints. Curtis’s customers now benefit from a product that not only dispenses high-quality cappuccinos but also reflects thoughtful design and innovation.

The partnership between Wilbur Curtis and IN2 exemplifies the power of strategic design and engineering collaboration. Partnering together, both IN2 and Curtis have set a new standard for beverage dispensing equipment that balances aesthetics, functionality, and manufacturing excellence.

Interested in learning more about how IN2 can help you innovate smarter? Contact us today to discuss your next project.