Prototyping Solutions for ~Pourri

IN2 International Case Study

Client Overview: ~Pourri, a well-known consumer products brand, had a specific challenge when they approached IN2 International. With an established product line and a strong market presence, ~Pourri was looking to improve the aesthetics and functionality of their packaging components, particularly the caps of their Poo~Pourri spray bottles. The goal was to replace the existing clear caps with a higher-quality, custom-designed black cap that would enhance the brand’s image while ensuring fit and performance.

IN2 International, with its expertise in manufacturing and prototyping, was tasked with creating a solution that would not only meet the visual and functional requirements but also scale for mass production. Over the years, this collaboration has grown and IN2 has successfully delivered millions of caps annually, showcasing its capability to scale production while maintaining quality and responsiveness.

The Challenge:

~Pourri came to IN2 with several distinct requirements for their cap design:

- Fit and Functionality: The new cap had to snap onto an existing bottle with a secure, positive lock engagement, ensuring it wouldn’t accidentally detach.

- Aesthetic Upgrades: ~Pourri sought to eliminate the existing clear cap and replace it with a sleek black one, adding a specific logo embossed on the top for brand consistency.

- Production Feasibility: The design needed to be both visually appealing and manufacturable at scale without compromising on quality or fit.

Timeline Sensitivity: With a quick turnaround expectation, IN2 had to deliver a working prototype efficiently while meeting all technical and aesthetic requirements.

The Solution: A Collaborative and Iterative Approach to Prototyping

When ~Pourri engaged IN2 International, the design process moved swiftly. The initial prototypes were crafted using CNC machining to create samples and verify the fit of the new cap. CNC machining provided the precision needed to ensure that the new design would securely snap onto the existing bottle without deforming during production.

IN2’s process for the Poo~Pourri cap project demonstrates the company’s dual approach to prototyping: one focused on rapid prototyping for market validation, and another for manufacturability at scale. IN2’s ability to bridge both needs allowed the team to move from concept to full-scale production in a short timeframe.

Key Technical Considerations:

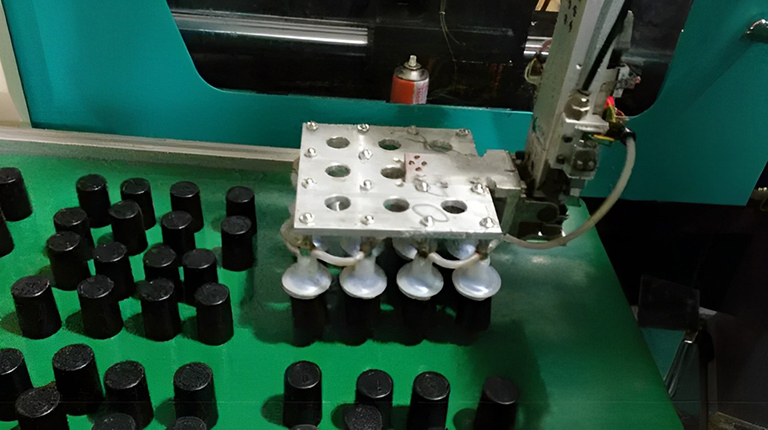

- Injection Molding and Tooling: To ensure the caps could be produced at scale, IN2 utilized injection molding, a process that required the development of a custom tool featuring an internal snap feature. The initial tool was an eight-cavity mold, which helped prove the production process’s viability. Once this mold was validated, additional molds were created to ramp up production efficiently.

- Ejection Method Development: A key challenge during production was developing a reliable ejection method to remove the caps from the mold without deforming the internal snap feature. IN2’s engineering team solved this challenge by designing a custom ejection system that maintained the integrity of the cap’s shape and function.

- Automation for High-Volume Production: Once the prototypes were validated and the production molds were proven, the team implemented an automated production line. This automation enabled IN2 to produce millions of units with minimal variance and high repeatability—critical in maintaining product quality over large production runs.

Results: From Prototypes to 100 Million Units

The collaboration with ~Pourri not only met the client’s expectations, but also allowed for a sustained partnership of over a decade. As of today, IN2 International has produced more than 100,000,000 caps for ~Pourri, a testament to the scalability and reliability of IN2’s manufacturing solutions.

Key Achievements:

- Design Validation: The initial prototypes were used to validate the design’s fit and aesthetic quality. ~Pourri’s specific branding requirements were met, including the intricate logo on the cap.

- Production Scalability: Once the design was validated, IN2 quickly scaled production, creating multiple molds to meet the client’s growing demand. This scalability highlights IN2’s ability to pivot from small-scale prototyping to full-scale manufacturing efficiently.

- Innovation in Production: IN2’s team continually optimized the production process, from custom ejection methods to automated systems, ensuring high-volume orders were met with consistent quality.

Ongoing Partnership: Adapting to New Requirements

Beyond the initial cap project, ~Pourri has continued to work with IN2 on new packaging innovations. Each new challenge, whether it’s an updated sprayer mechanism or alternative packaging designs like glass bottles or cardboard tubes, reinforces IN2’s ability to partner with clients at every stage of the product lifecycle.

Conclusion:

The success of this project highlights IN2 International’s expertise in balancing design complexity, functionality, and manufacturability. From prototyping to large-scale production, IN2’s responsive and precise approach allowed ~Pourri to achieve their goal of elevating their product’s aesthetic and functional appeal. This case study stands as an example of how IN2 partners with established brands to bring their visions to life while preparing for production at scale